Alberta Slip

Description

Fine-grained, plastic, dark brown burning clay that melts to form glossy rich beanpot-brown glazes at high fire reduction (cone 10) and a glossy amber brown at cone 6 oxidation (with frit addition).

Historically, Albany Slip was a 'standard' within the North American pottery community and ceramic industry. It was a silty glacial clay that melted easily at high temperatures to form a 'natural glaze'. With additions of a little frit, feldspar, lithium carbonate, or gerstley borate, it produced a wide range of earth tone glazes in middle fire oxidation. Albany Slip responded well to dark coloring oxides and stains to produce deep blacks, browns and even blues. It produced glazes that had a low thermal expansion (to avoid crazing). At cone 10R, with only a small iron addition, excellent tenmoku surfaces were possible. In the late 1980s Hamill and Gillespie Co. discontinued Albany Slip leaving thousands of users with less than ideal alternatives.

The outside glaze is GA6-B, the liner glaze is GR6-A. On M340 at cone 6 oxidation. These glazes are just Alberta Slip and Ravenscrag Slip with 20% added frit. Both of these apply well and fire to a brilliant surface with minimal defects if firings are slow cooled.

This is 100% Alberta Slip (outside) and 100% Ravenscrag Slip liner glaze. White stoneware H450 clay fired to cone 10R. Both glazes have been made using a blend of calcine and roast (60:40 and 50:50). By Tony Hansen.

In 1988 we formulated Alberta Slip as the first widely available substitute material. We published the process we used to do it. Alberta Slip had the same chemistry and very similar firing properties (the original material was somewhat variable, we patterned our work after an average sample). Alberta Slip has been proven over many years and is used by people across North America to make many stunning glazes. Other substitutes have appeared from time to time but no others have had the success of this material.

News

June 2023: We began producing this material at 60 mesh, run #7086. This greatly streamlines our ability to keep up with demand. We recommend sieving glazes through 80 mesh maximum, this removes particles that could otherwise cause roughness on contour edges of fired glazes. Only one pass is needed.

Preparation

Left: Raw Alberta Slip powder. Right: Roasted at 1080F. This is a plastic clay, thus it has a significant drying shrinkage. Where a glaze is applied thickly or the percentage of Alberta Slip is high, shrinkage cracks (which produce crawling during firing) will occur. We recommend a mix of roast and raw material in recipes. Roasting the Alberta Slip powder at 1000F greatly reduces the shrinkage. Use a firing rate and hold-time-at-1000F appropriate for the wall thickness and size of your bisque vessels (e.g. 500F/hr and 30 minutes for thin walled small vessels, slower and longer hold for large ones). If any of the powder within is black, increase hold time. Adjust proportions as needed (more roast if the glaze cracks on drying or more raw if it is drying too powdery or not bonding well).

The roasted material has a weight-loss of about 3% on firing (vs. 9% for the raw powder). This difference can be ignored in most cases. But, to be more precise, use 3% less of the roasted powder (multiply the amount by 0.97). For example, suppose you need 1000 grams of a 50:50 raw:cacline Alberta Slip mix for a glaze recipe. Use 500 raw and 500*.97=485 roast.

Alberta slip is much more plastic than Albany was. This means that it dries harder and less dusty but also has a higher drying shrinkage. Thus, part of the material needs to be roasted (to cut shrinkage). Roasting is absolutely necessary to prevent cracking as the glaze dries (and thus crawling during firing). Using a mix of raost:raw also enables control over slurry properties (e.g. with a 50:50 blend in a glaze having 80-100% Alberta Slip, the slurry suspends and applies well, dries hard and does not crack for normal thickness).

We roast it to 1000F, high enough to destroy the plasticity (firing too high can calcine it, sintering particles together and creating grit). Use a firing rate and hold-time-at-1000F appropriate for the wall thickness and size of your bisque vessels (e.g. 500F/hr and 30 minute hold for thin-walled small vessels, slower and longer hold for large ones). The first time roasting will be experimental, any black powder remaining in the center is an indication of insufficient hold time at the end of the firing).

Adjusting percentages: This roasted material has an LOI of about 3% (vs. 9% for the raw powder). This difference can be ignored in most cases. But if you want to be more precise, use 3% less of the roasted powder (multiply the amount by 0.97). For example, suppose you need 1000 grams of a 50:50 raw:cacline Alberta Slip mix for a glaze recipe. Use 500 raw and 500*.97=485 roast. Then watch how the slurry performs and adjust the proportions if needed (more roast if the glaze cracks on drying or more raw if it is drying too powdery or not bonding well).

Alberta Slip is a plastic clay, if used in recipes in higher percentages, it can cause them to crack during drying. A mix of roast:raw must be used.

Process Properties

In our studio we use pure Alberta Slip as a glaze at cone 10R. We mix it using a 60:40 roasted:raw mix of Alberta Slip powder. Glazes are most often prepared using the traditional method of simply adding water until the desired consistency is achieved (rather than targeting specific gravities and conditioning with flocculants). This works well in recipes having a high percentage of Alberta Slip, the clay:roast mix (which you control) coupled with its predominance in the recipe creates a slurry that applies well across a range of viscosities without the help of any rheological chemicals. Care is needed for more viscous slurries, these tend to go on too thick. When frit is added to make it melt at lower temperatures, lower specific gravities (higher water content) will likely be needed. In recipes that have low percentages of Alberta Slip, calcining is likely not needed and they can be treated normally (gelled to a thixotropic state).

If multiple layers of Alberta-Slip-based glazes need to be applied, CMC Gum additions will be needed to prevent cracking and/or release from the bisque.

Firing

Like classic Albany Slip, Alberta Slip begins melting at middle temperatures and by cone 10 it produces a glossy brown in oxidation and a tenmoku in reduction. One of the major advantages of this material is the ease with which it can be adapted to different temperatures. 20% frit produces very good melting at cone 6 and 50% melts at cone 06.

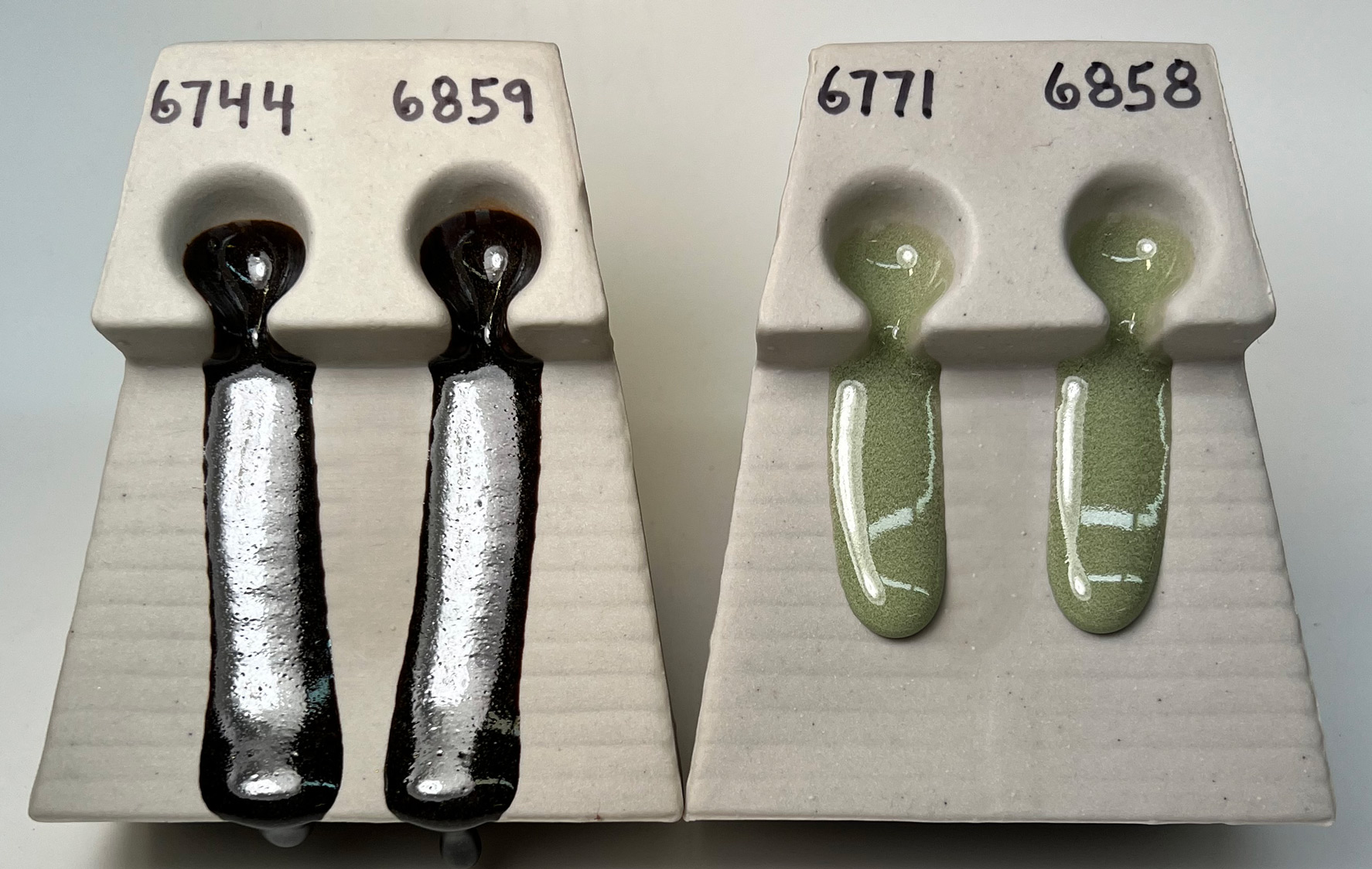

Melt flow tests of two runs of Alberta slip and Ravenscrag Slip (both fired at cone 10R). These demonstrate the kind of consistency we have been able to achieve over many years.

Since it is basically a clay material, it generates a significant amount of gas as it decomposes during melting. However, despite this, it can produce stunningly smooth and defect-free surfaces (we do not have a good explanation for this). For example, GA6-B produces a far better transparent for dark burning bodies like M390 or Coffee Clay.

Glazing

There are some coarser particles in the material so sieve your glazes through 80 mesh or finer before use (the increased effort to screen finer than 80 mesh is not generally worth the trouble).

As a raw material, the plasticity of Alberta Slip makes it an ideal base for 'slip glazes' for use on leather-hard ware. These do not need to be made using a mix of roast and raw, the pure raw powder is better.

Like Albany Slip, Alberta Slip has a low thermal expansion. Thus glazes will tend to be craze free. Glazes having significant lithium carbonate can lower the expansion enough to produce shivering. Using this with materials containing high K2O/Na2O can produce glazes that craze (especially on porcelains).

Our melt-flow tests show that Alberta Slip displays the same characteristic blistering as Albany in fast firings. However, it does not melt quite as vigorously (although it does flow as well). In addition, Alberta slip is not as inherently fine and silty as Albany. Alberta slip will tend to gel glaze suspensions a little more than Albany did and it does not deflocculate easily.

Glaze Recipes

Since Alberta Slip fires by itself to a dark gloss at cone 10 and a honey clear at cone 6 (with 20% added frit). It is essential to use a mix of roasted and raw Alberta Slip to control the degree of shrinkage (and therefore drying cracks).

Common Recipes for Cone 6

- Amber Transparent - GA6-B

- Gloss Black - G3914A

- Rutile Blue - GA6-C

- Oatmeal - GA6-F

- Glossy Brown - GA6-D

- Lithium Brown - GA6-G, GA6-G1 and G3933EF

Common Recipes for Cone 10R

Physical Properties

Drying Shrinkage: 5.0-6.0%

Melt Flow:

Cone 6: 3.0-4.0 cm Cone 8: 5.0-6.0 cm Cone 10: 7.0-8.0 cm

Sieve Analysis (Tyler mesh):

+100: 0.3-0.5%

Chemical Analysis

If your analysis data for this material is different it is not because the material changed, but because we have switched to an actual assay instead of a calculated analysis.

CaO 5.9 K2O 3.5 MgO 3.9 Na2O 2.2 TiO2 0.3 Al2O3 15.2 P2O5 0.1 SiO2 53.54 Fe2O3 4.5 LOI 9.2%

Downloads

- Brochure for double-sided printing (uncheck the Fit to Page checkbox when printing or it will be too small)

Gallery

Plainsman H450 (buff stoneware) mugs fired at cone 10R with pure Alberta Slip on the outsides, G1947U transparent (left) and pure Ravenscrag Slip liner glaze. By Tony Hansen.

M340 with Alberta Slip GA6-C rutile blue glaze. Cone 6. L3954B black engobe was applied inside and half way down the outside during leather hard stage.

All of these mugs are made from glazes whose major component is either Alberta Slip or Ravenscrag Slip. They are all fired at cone 10R.