F100G

Description

White grogged sculpture body made from talc and ball clay (the same recipe as L213 but 20% of the talc has been substituted for 35 mesh grog and silica sand). This body is commonly used to make large pieces.

News

We no longer produce this but you can make your own by wedging in sand and/or grog to our Snow body. An advantage of this approach is better glaze fit than was afforded by F100G.

Process Properties

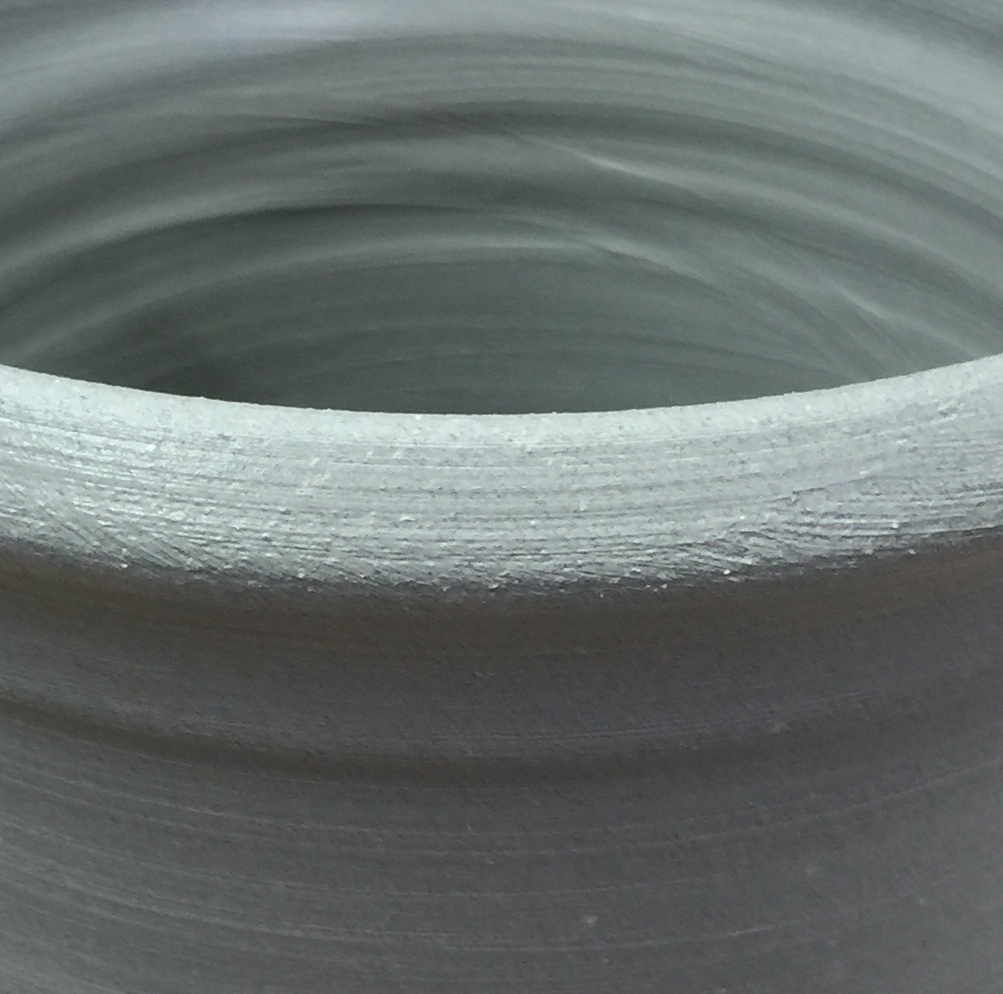

Talc/Ball clay bodies are very plastic and at the same time dry well. The additional fine silica sand and grog give this body even better drying capabilities. Despite this, F100G feels quite smooth. We recommend F100G when sculptors need high certainty that ware can be dried without cracks while still having a relatively smooth fired surface. One caution: Its dry strength is fairly low, handle dry ware with care.

Firing

Very white burning. The high plasticity of F100G slows drying and makes it susceptible to failure in the early water-smoking phase of firing. Make sure pieces are thoroughly dry before firing. Preheat your kiln overnight, or even for a full day, if pieces are large.

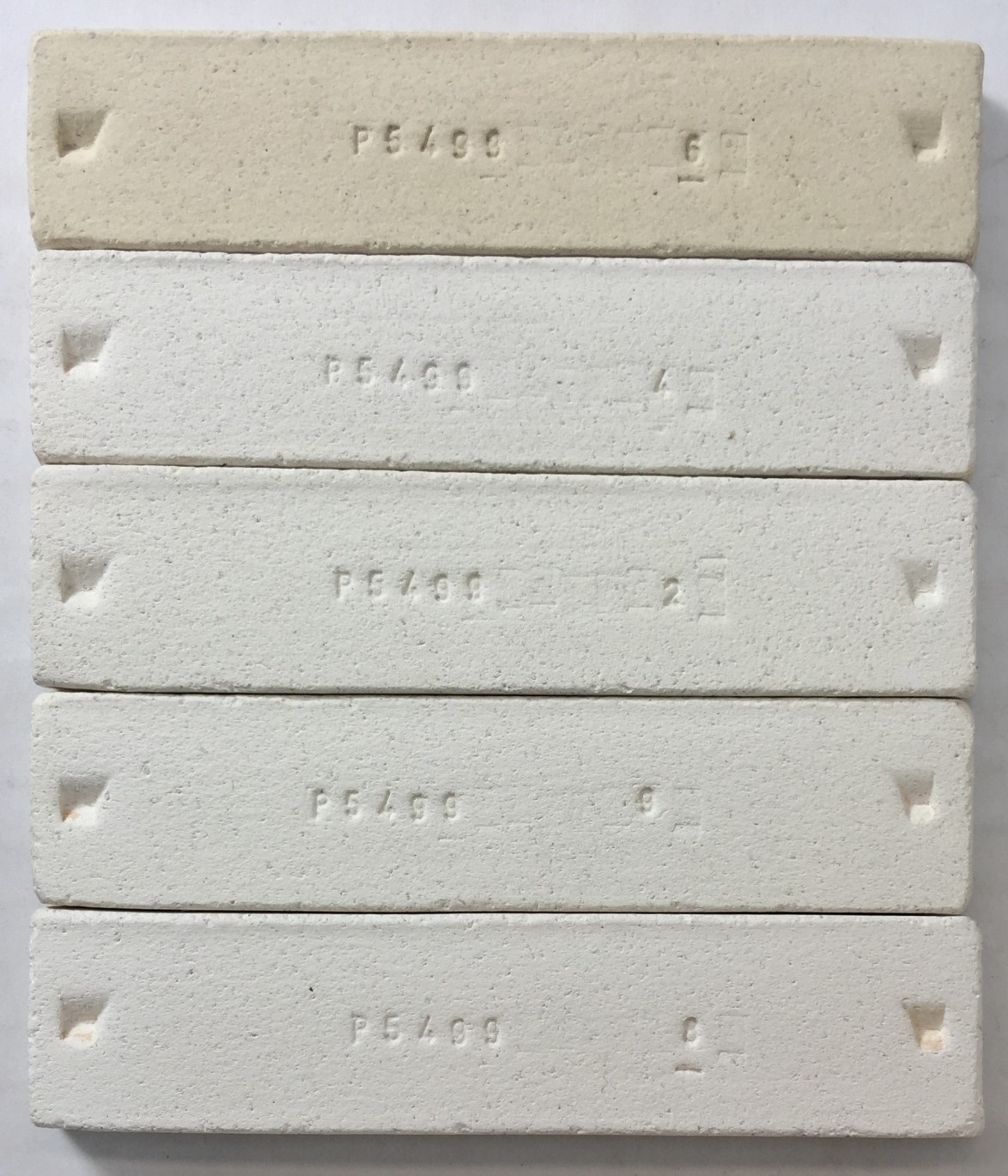

F100G can be fired to cone 4 fairly safely. At cone 6 it still appears to be stable visually, however the fired shrinkage and porosity have already reversed (indicating firing volatility).

Glazing

Most customers use this as a sculpture body, they do not glaze pieces. Although we have had some success with the G2931K base glaze, like F100, we do not have any specific glaze recipe recommendations - you will need to experiment to find one available to you that fits.

Thermal Expansion

We do not supply thermal expansion values. If a chart is supplied here, please view it only as a way to compare one body with another. Please note that, although you may calculate the thermal expansion of a glaze, this cannot be done for clay bodies since they do not melt. The best way to fit glazes to clay bodies is by testing, evaluation, adjustment and retesting. For example, if a glaze crazes, adjust its recipe to bring the expansion down, fire a glazed piece and thermal stress it (using an IWCT test, 300F into ice-water). If it still crazes, repeat the process.

Physical Properties

Drying Shrinkage: 4.5-5.5% Dry Strength: n/a Drying Factor: B110 Water Content: 19.5-20.5% Mar 99 Dry Density: 1.95

Sieve Analysis (Tyler mesh):

+48 (300 microns): 0.0-0.6% 48-65 (300-210 microns): 0.4-0.8 65-100 (210-149 microns): 2.5-3.5 100-150 (149-106 microns): 2.0-3.0 150-200 (106-75 microns): 5.5-7.5 200-325 (75-45 microns): 7.0-10.0

Fired Shrinkage:

Cone 04: 1.0-2.0% Cone 02: 1.5-2.5 Cone 2: 2.0-3.0 Cone 4: 2.5-3.5 Cone 6: 2.0-3.0

Fired Absorption:

Cone 04: 11-14% Cone 02: 10.5-13 Cone 2: 10-12 Cone 4: 10-11.5 Cone 6: 9.5-11