Tapper Clay V

Description

A blend of three of our consistent, refractory native materials with coarse aggregate particles that impart the thermal properties necessary for a tapper clay. It is vacuum pugged to produce a pliable and extrudable material with good injection properties.

-Compared to our Tapper II material, it has more and and much larger aggregate particles to better channel internal steam pressure and reduce, popping, fracturing, cracking and shrinkage.

-An additional clay has been added to the blend to effect a higher alumina content.

Heating

Clays normally require hours to dry and crack or explode if pushed to dry too fast (thus Tapper clays must perform uncharacteristic functions). However with additions of sand and aggregate to provide micro-channels to vent steam, tapper clays can be force-dried much more quickly. In addition, many clays form a 'glassy skin' around particles when exposed to 1200-1300C, and this further impedes the escape of steam. However our Tapper mix is made from refractory materials that are low in K2O and Na2O and remain stable (it deforms and begins the melting process at about 1600C).

Physical Properties

Drying Shrinkage: 4.5-5.5% Water Content: 17-18% Service Temperature: 1300-1350C Bond Type: Heat Minimum Time Before Firing: 0 hr. Storage Life: 6 months Packaging: 20 kg box (44 lb)

Sieve Analysis (Tyler mesh):

+48 (300 microns): 8.0-11.0% 48-65 (300-210 microns): 7.0-10.0 65-100 (210-149 microns): 4.0-8.0 100-150 (149-106 microns): 10.0-15.0 150-200 (106-75 microns): 3.0-8.0 200-325 (75-45 microns): 5.0-10.0

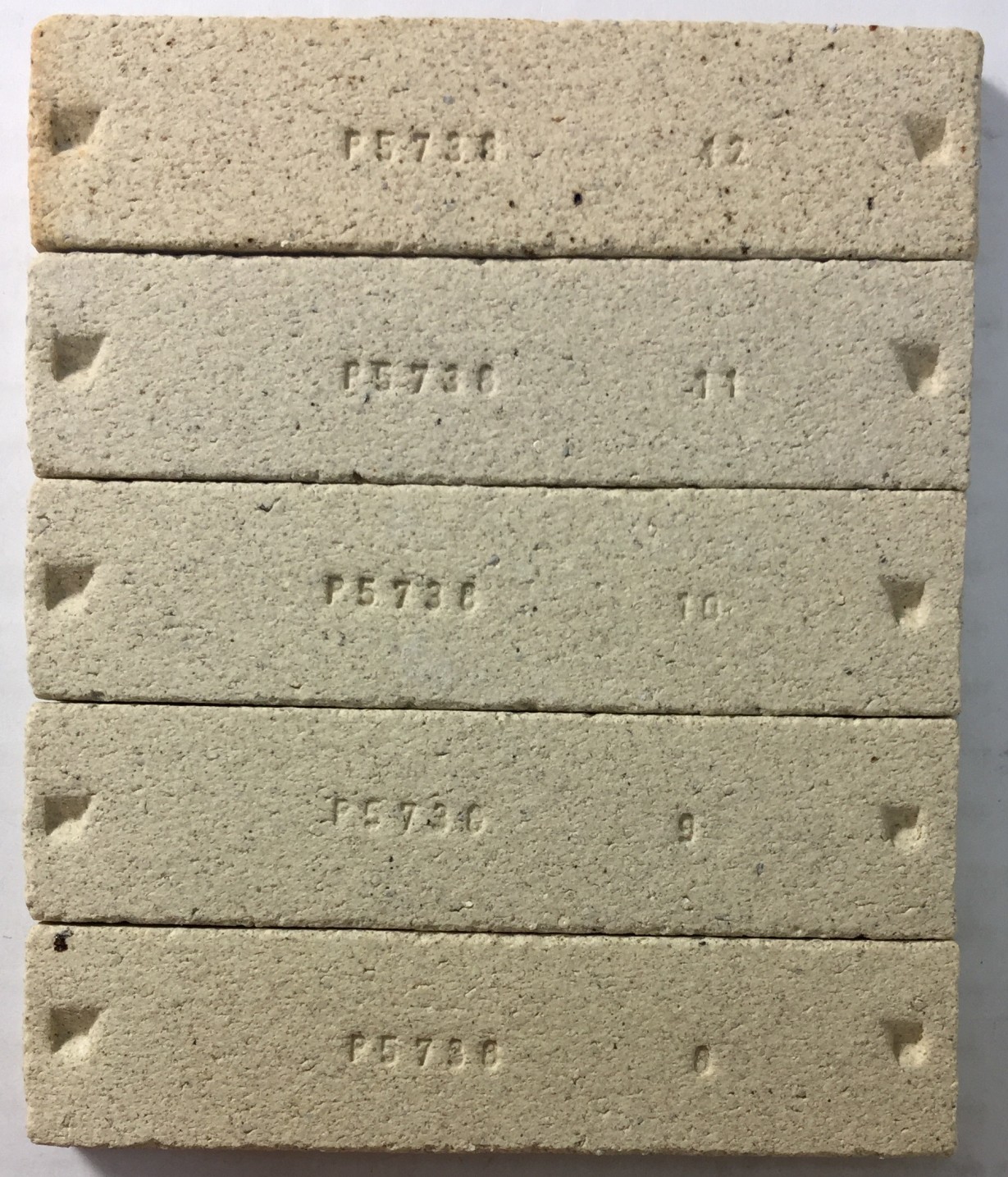

Burned Shrinkage:

1220C: 1.5-2.0%

1260C: 1.8-2.3

1300C: 2.0-2.5

Burned Porosity:

1220C: 10-11%

1260C: 9-10

1300C: 8-9